From a throat swab collection to the nucleic acid test report on the phone, what has gone through in between? Let us go into the COVID-19 Nucleic Acid Testing Laboratory of the Medical Laboratory Department of Bei’an First People’s Hospital, and follow the medical staff to reveal the whole process of nucleic acid testing.

First of all, the sampling personnel need to wear a full set of protective measures such as medical protective masks, goggles, isolation gowns, double-layer gloves, and waterproof boots for specimen collection. After collecting the throat swab of the subject, the sampling personnel immersed the swab head in the virus preservation solution to prevent the degradation of viral nucleic acid.

Secondly, the virus must be inactivated after checking the test specimens. When the specimen arrives in the laboratory, the specimen needs to be shaken and mixed to make the cells collected on the throat swab fall off.

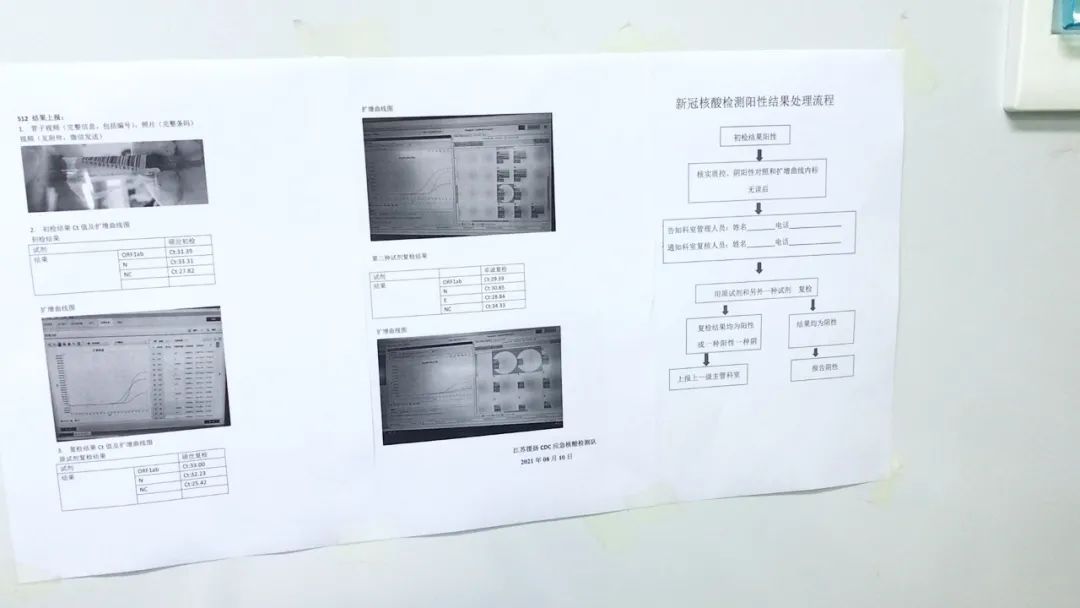

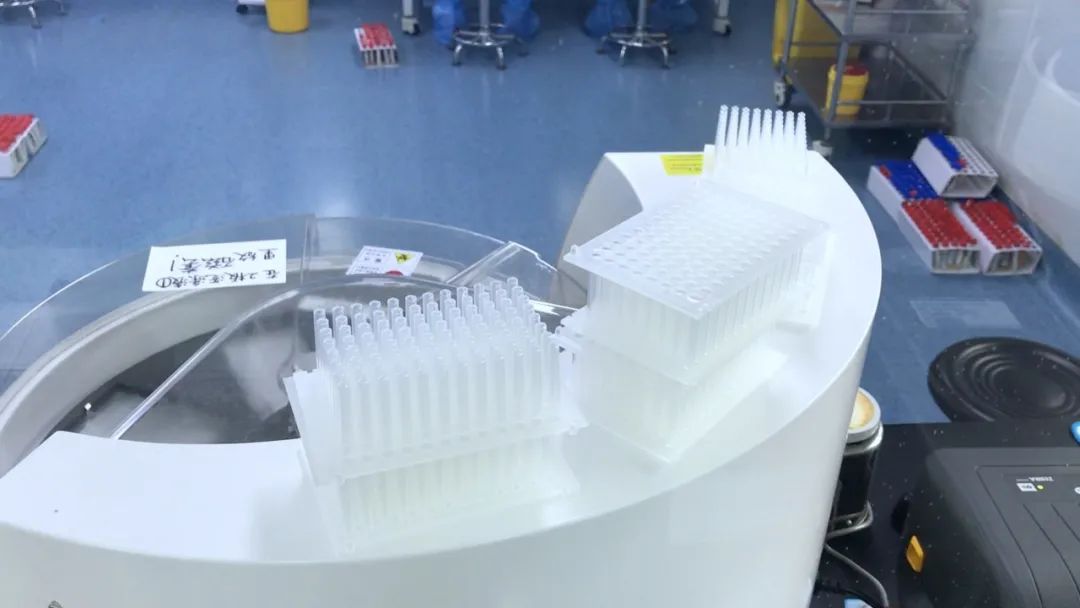

Then, the inspector extracts the nucleic acid from the specimen before it can be amplified and interpreted. Each sample must perform such a set of actions. In order to avoid mistakes and prevent cross-contamination, the inspectors need to be highly focused. Add all the extracted nucleic acids to the amplification reaction solution and put them into the thermal cycler, edit the specimen numbers of all samples, mark the positions of the positive and negative control wells, and select the corresponding procedures to start the amplification process.

In addition to the above steps, quality control is also required. In each test, the staff needs to add negative control, weak positive quality control, positive control, etc., to test the quality of the whole process of the test, to ensure the reliability and accuracy of the test results.

Â

Source:Â I am Beian

Seed Opener Blade Assembly Housing

This classification mainly includes the aluminum or zinc alloy die casting parts using in Seed Opener area. In the die casting process,higher specific pressure is required, so that higher filling speed can be obtained.which is beneficial for alloy to overcome mold filling resistance.and effectively fill each part of the cavity.The Casting General Tolerance is Grade GB-CT4.

Process Technology: High pressure die casting, Cold Chamber

Product Dimensions: Customized

Casting General Tolerance: Grade GB-CT4

Flow Processes: Die casting, Degating to remove the residual of the gate, Polishing and Deburring to remove the burrs, Polishing to remove the parting line, flash,CNC Turning, Cleaning, Packaging, Storaging, Shipping

Control Measure: Incoming Material Test, First Article inspection, Routing inspection, Final item inspection, and Outgoing quality control

Inspection Equipment: CMM, Caliper, Plug Gage, Screw Gauge

Application: Agriculture Parts

Certificate: IATF16949:2016,ISO14001:2015,ISO45001:2018

Lead Time: 30-35 days

Trade Term: FOB Ningbo

Seed Assembly Die Casting Parts,Aluminum Seed Blade Assembly Housing,Die Casting Seed Blade Housing

NINGBO ZHENHAI BOLANG METAL PRODUCTS FACTORY , https://www.casting-part.com